Technical Specifications

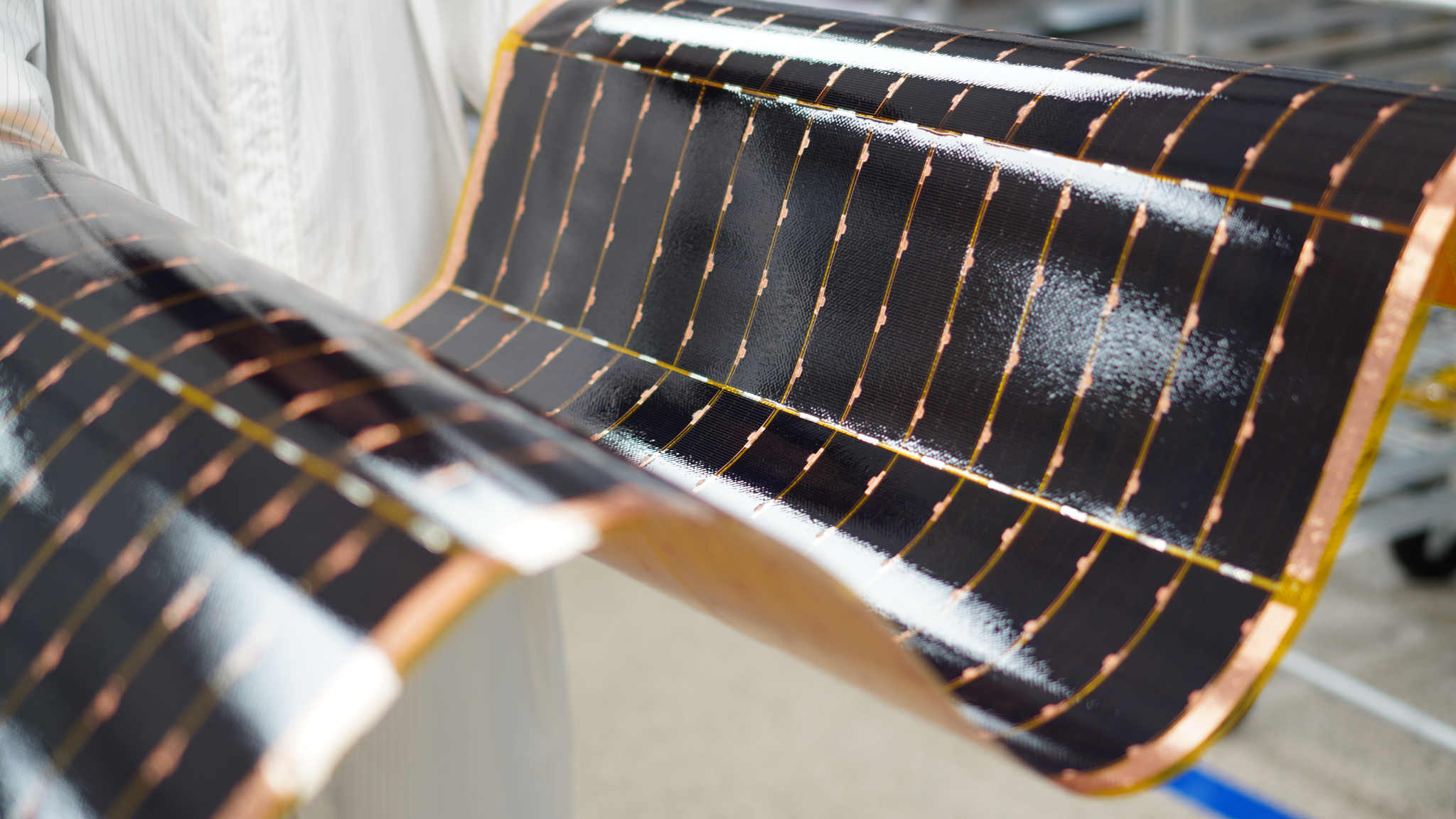

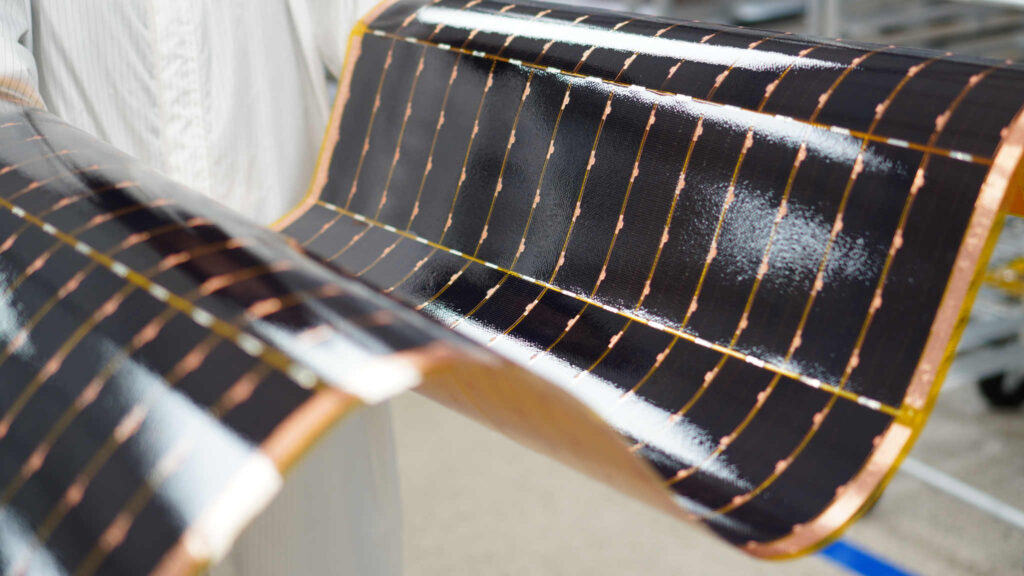

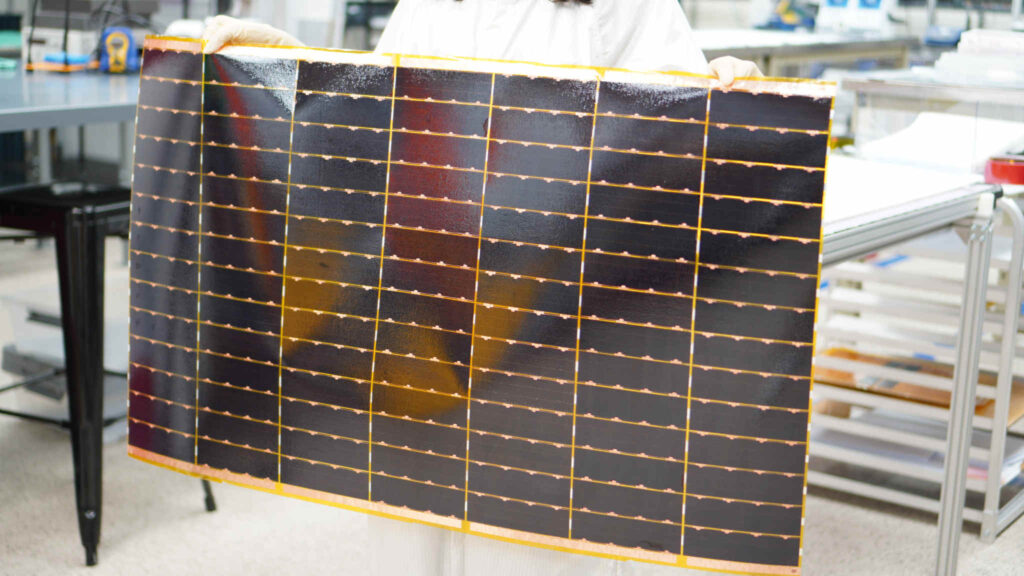

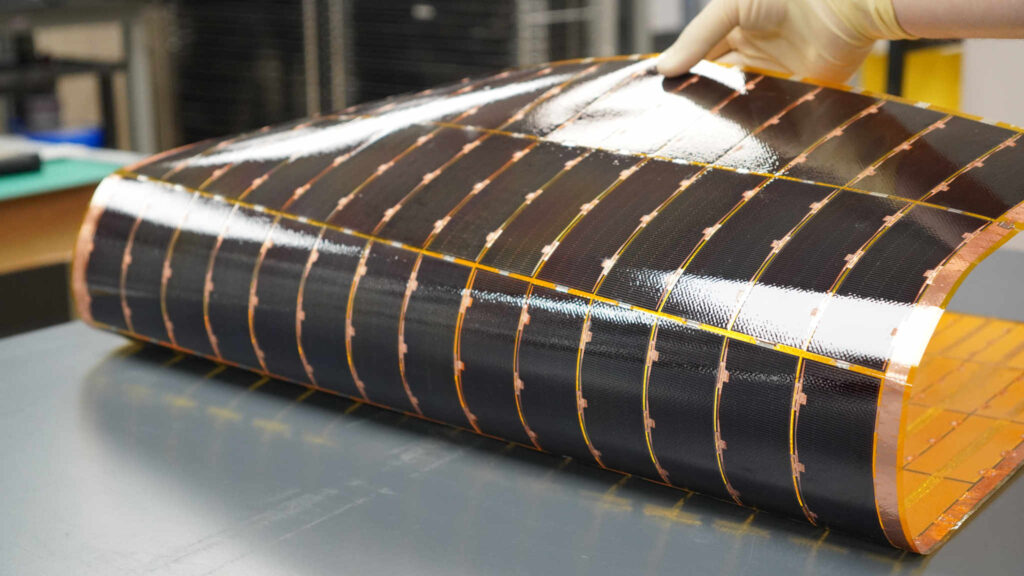

Our unique packaging replaces cover glass and bulky substrates with polymer and ceramic films to produce a thin and flexible solar power module. Solestial SPMs can be safely rolled into a 5 cm bend radius.

Low mass

Low mass

Our total solar power module mass is 508 g/m2. This includes the cells, interconnects, and protective film layers.

Bifaciality

Bifaciality

Bifacial technology allows a photovoltaic module to generate power from light received on either side of the module. Our silicon heterojunction solar cells are intrinsically bifacial, allowing us to rethink packaging for our solar power modules to maximize power. Bifacial technology has the potential to change the way we think about solar arrays and spacecraft orientation. This technology is available to our customers on demand.

Long-lasting cell-to-cell interconnects

Long-lasting cell-to-cell interconnects

Our proprietary cell-to-cell interconnection technology is optimized for very thin crystalline silicon solar cells that can withstand up to 10 years in a variety of destinations in space.

UV and AO protective coatings

UV and AO protective coatings

The AO and UV protective coatings leveraged by Solestial have been used in the space solar power industry for many years and are proven to protect modules from the damage encountered in low Earth orbits.

Scalable automated manufacturing

Scalable automated manufacturing

Solestial solar power modules are designed for manufacturing using processes derived from the terrestrial solar and PCB industries that can scale to gigawatts as the space industry grows. Solestial’s technology allows us to manufacture large-scale modules in weeks, not months or years.

Contact Us

Solestial, Inc.