Technical Specifications

Our solar cells can effectively anneal electron and proton radiation damage at normal operating temperatures as low as 65°C (1366 W/m2, maximum power operation point). To achieve low temperature annealing, Solestial cells are ultrathin (presently 60 microns and can be as thin as 20 microns) and utilize proprietary defect engineering. Radiation damage accumulated in our cells during cold and dark periods are effectively mitigated by annealing that occurs during bright and warm periods, resulting in an overall reduction in radiation-induced degradation.

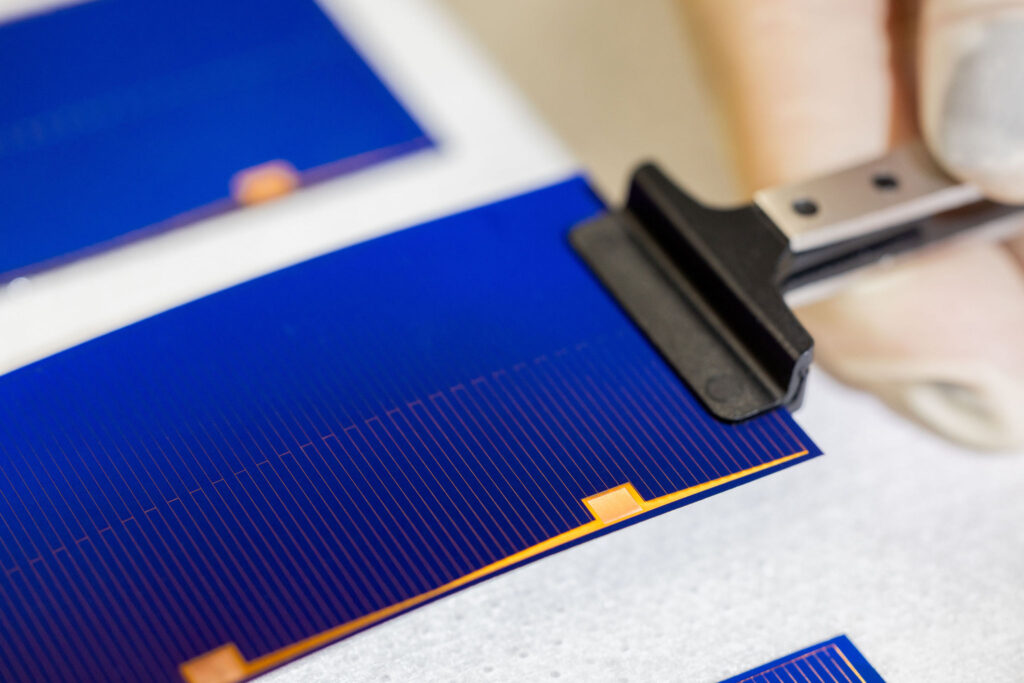

Ultrathin cell

Ultrathin cell

Solestial’s unique process flow allows us to mass produce ultrathin silicon solar cells using automated production equipment. To achieve high efficiency with ultrathin silicon wafers, we use silicon heterojunction technology.

Silicon heterojunction technology

Silicon heterojunction technology

Solestial is leveraging three decades of progress in terrestrial silicon heterojunction technology to mass produce ultrathin solar cells. Silicon heterojunction technology allows us make cells at very low temperatures, and without introducing stress, enabling cells that are 60 microns. Silicon heterojunction technology achieves the best possible surface passivation, enabling high efficiency on very thin wafers.

20%* beginning-of-life efficiency

20%* beginning-of-life efficiency

Solestial cells will achieve a competitive 20%* efficiency in production in 2025, and we expect to increase efficiency to 23% over the next few years, at which point we will approach the engineering limit for efficiency among this technology.

Potential for over 30% efficiency

Potential for over 30% efficiency

The next step for silicon solar technology is two-junction tandem integration. Recently, perovskite has been developed as a perfect top cell partner for silicon. We expect that perovskite technology will mature over the next 5-10 years to give our silicon technology a 10% absolute efficiency boost.

Fewer bypass diodes

Fewer bypass diodes

Silicon heterojunction technology enables higher reverse breakdown voltage and hot spot tolerance, allowing us to use fewer bypass diodes.

Low temperature coefficient

Low temperature coefficient

Silicon heterojunction technology achieves a low temperature coefficient. As a result, Solestial cells produce more power than diffused junction silicon solar cells. (1% absolute efficiency gain at 80°C versus terrestrial silicon solar cells.)

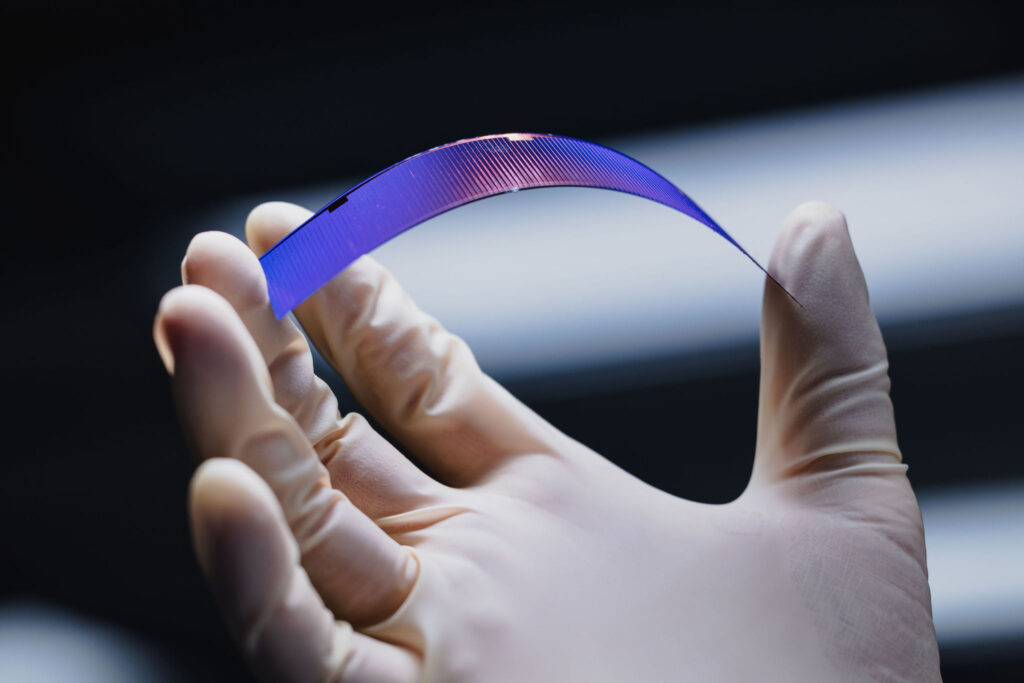

Robust metallization

Robust metallization

To allow for more robust cell-to-cell interconnects, we replace the screen-printed silver metallization used in terrestrial silicon cells with electroplated copper. We also cap copper with protective metal layers to avoid corrosion.

Customizable solar cell shape and size

Customizable solar cell shape and size

Even with automated production, we can customize the size of our solar cells for each customer. We accomplish this by leveraging affordable terrestrial solar wafers, which better allow for flexibility in cell sizing. We optimize packing density and voltage for each module we produce to provide our customers with better design options.

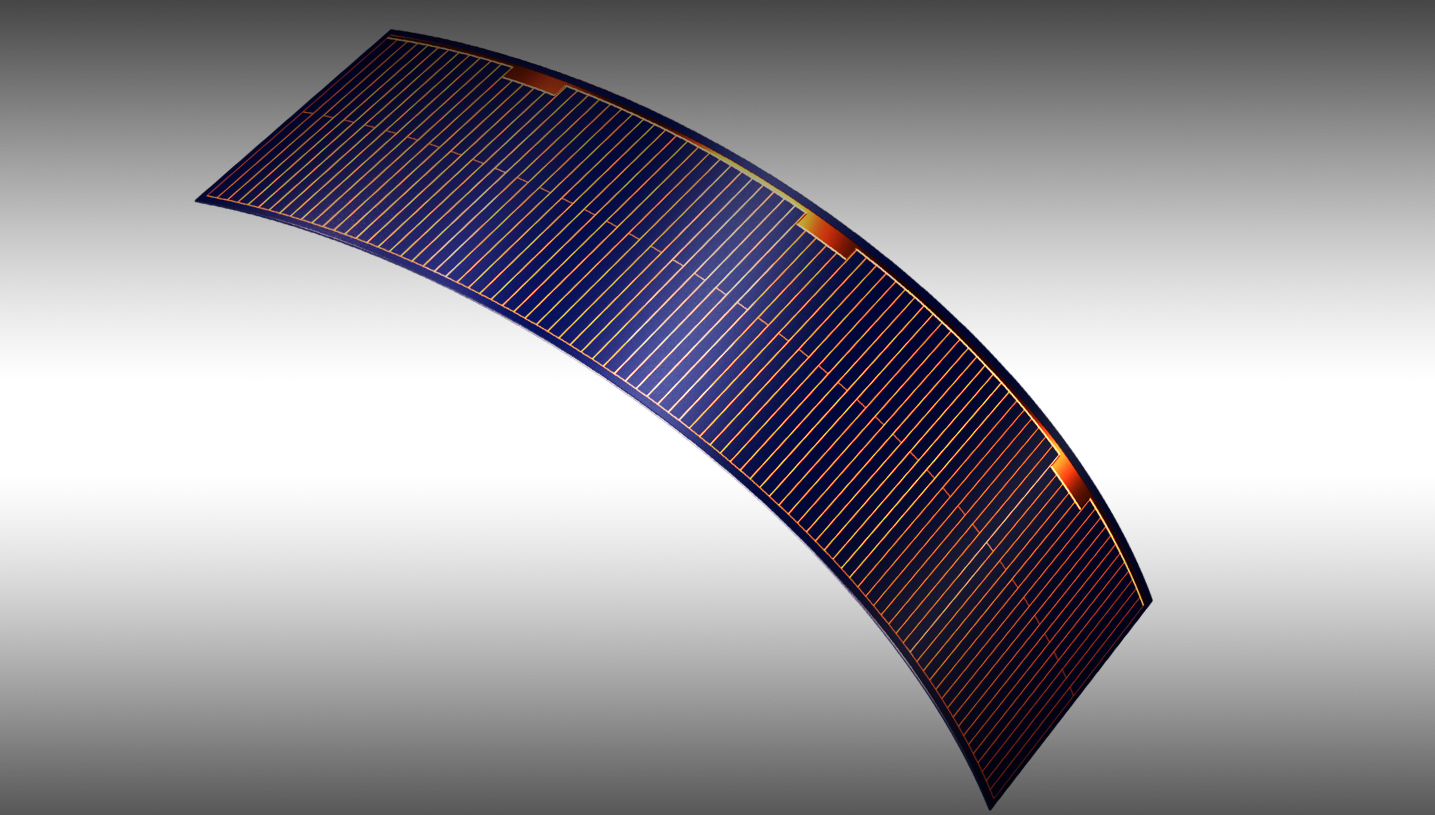

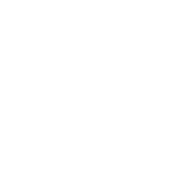

Low mass and flexible

Low mass and flexible

Our solar cells achieve an extremely low mass and bending radius, enabling novel solar power module assembly and solar array deployment concepts.

Contact Us

Solestial, Inc.